At Thermo-Electra, we believe in the power of collaboration and customer-focused engineering. A recent project with RIFT perfectly demonstrates how our technology aligns seamlessly with the innovative ambitions of our customers.

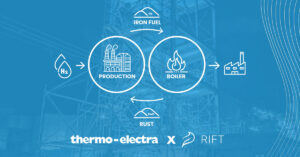

RIFT is pioneering a unique, circular energy technology: Iron Fuel Technology™. This innovation functions like a rechargeable battery for heat generation, using iron powder as an energy carrier. Through controlled combustion in a specially designed boiler, RIFT produces heat in the form of steam, hot water, or hot air, without direct CO₂ emissions and with exceptionally low NOx emissions. After combustion, the resulting iron oxide is collected as a solid offtake, transported, and then reduced back to iron fuel elsewhere using hydrogen.

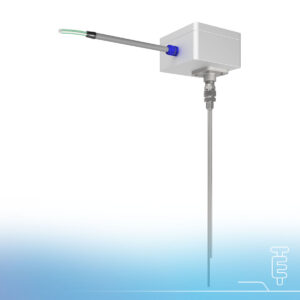

Following an on-site visit to understand RIFT’s process requirements, Thermo-Electra engineered a fully customized multipoint temperature sensor tailored to their technical and process needs. The sensor integrates more than 10 measurement points within a single robust assembly. This enables RIFT to precisely monitor temperatures at multiple levels within their combustion process. Essential for optimization, safety, and sustainability.

This project highlights what Thermo-Electra stands for:

- Tailor-made solutions designed to fit the customer’s process

- Technical expertise and consultation

- Fast turnaround from concept to production

Our partnership with RIFT proves that innovation begins with a meaningful collaboration, and that the right measurement solution can make all the difference in advancing sustainable technology.