Due to the continued requirement to improve the measurement quality and service life of temperature sensors, it is necessary to find a more suitable alternative for some applications. One of the applications of our temperature sensors is in the petrochemical industry. For one of our customers within the petrochemical industry, we developed a specifically tailor-made temperature sensor that is used for temperature measurement in hydrocracking/hydrotreating reactors. During hydrocracking, the molecular structure of oil undergoes a transformation. The molecules are “cracked” and fragmented, after which they are converted into more stable molecular structures. Read more about our unique solution that we have created in collaboration with our customer.

How we worked

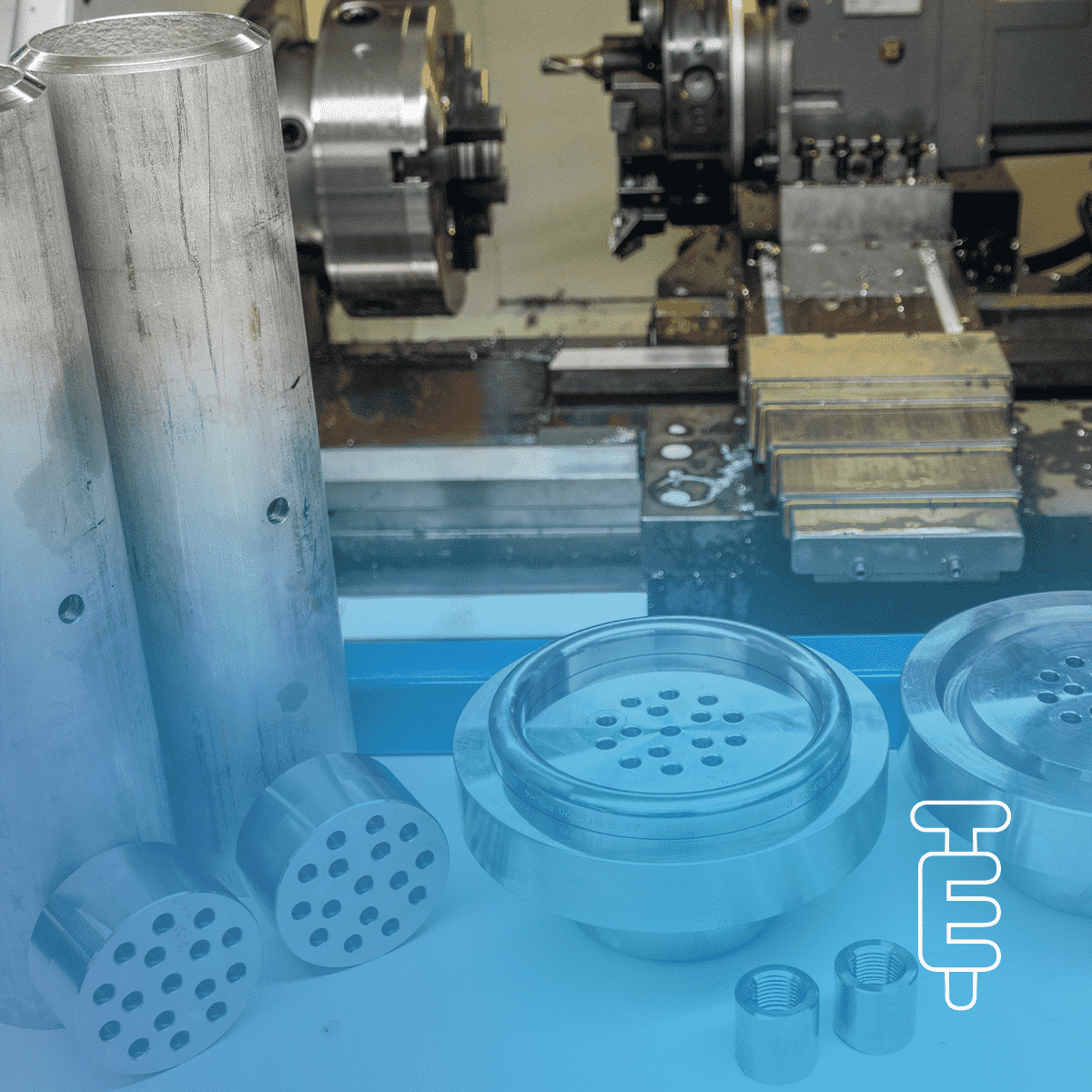

In addition to our standard range, we have been developing and producing customized solutions in the field of thermocouple and Pt100 temperature sensors since 1962. Our temperature solutions are used in various industries, including petrochemicals. Together with this customer we inventoried the wishes, but we also delved deeper into the process requirements and where the process limitations lie. Once this had been fully mapped out, we were able to find a solution that suited perfectly with the help of our in-house engineering department. By involving the customer in the process, knowledge and expertise are exchanged to achieve the best end result.

The solution

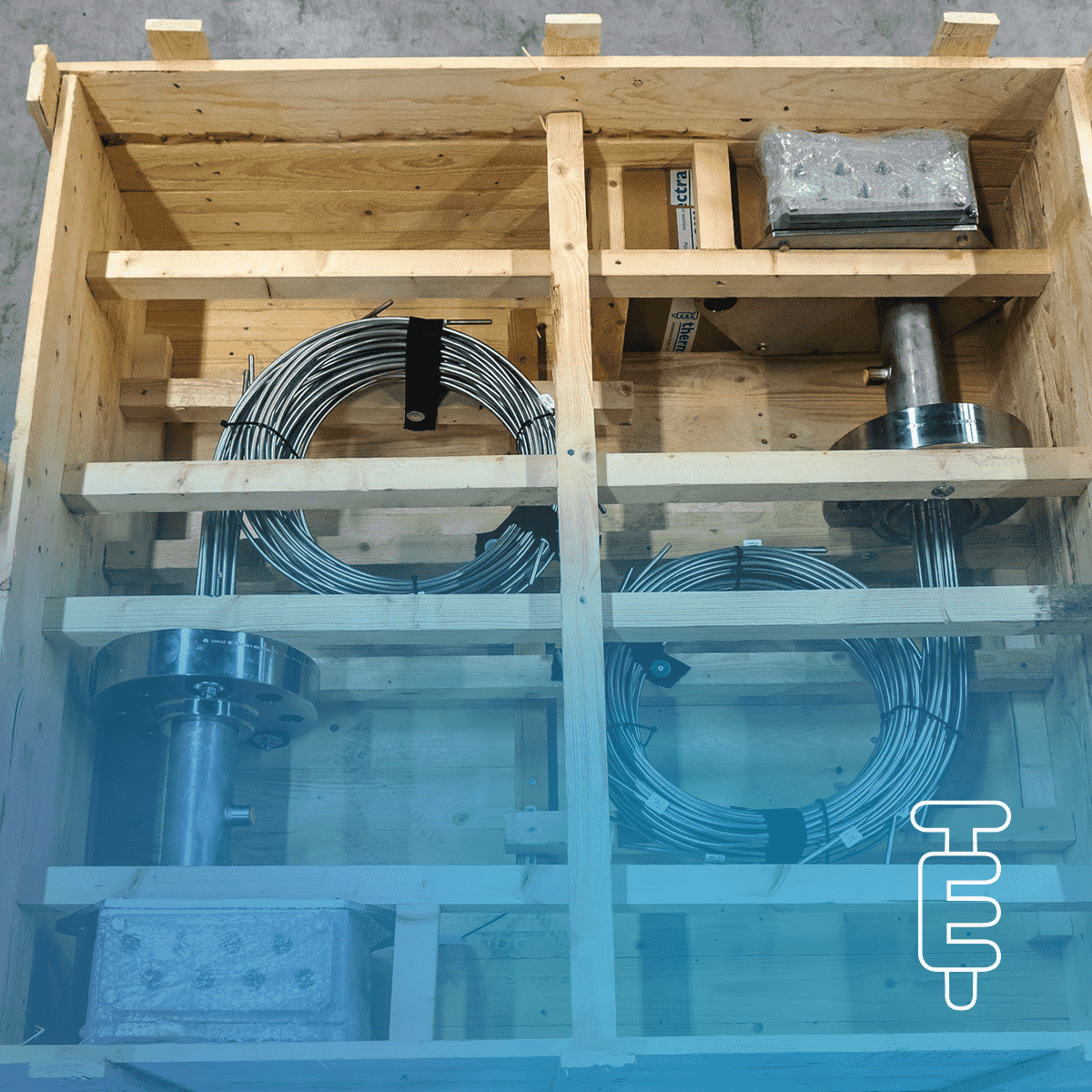

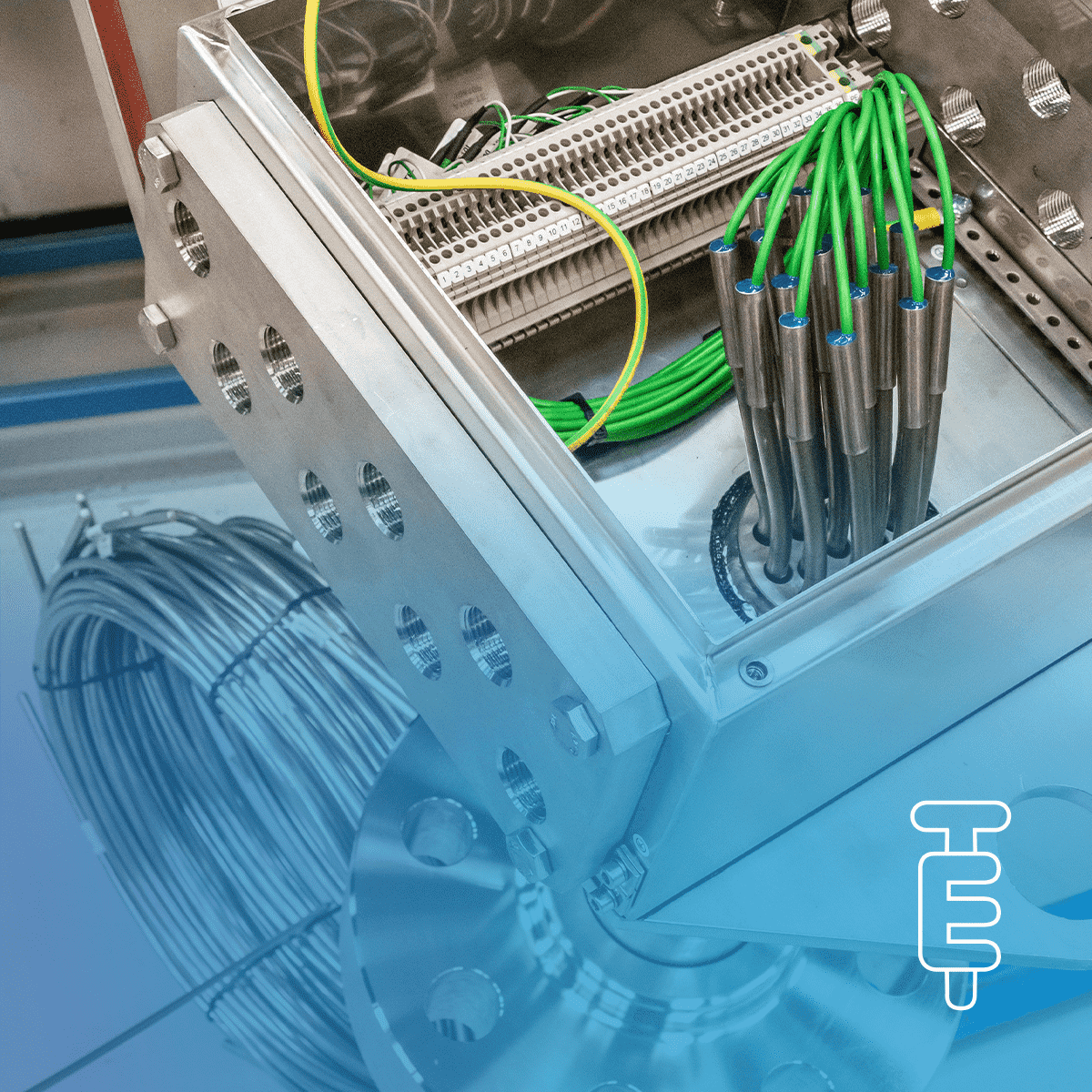

In order to properly monitor the process in these impressive reactors, the requirement for high-quality multipoint temperature sensors is essential. The sensors support the option of passing multiple sensors through a limited throughput, thermocouple nozzle, where they are rerouted to internal support trays according to our customers’ design guides. This limited conduit, the thermocouple nozzle, is where our sensors come into place with special soldering. This solution allows us to have just one heavy-duty flange that is suitable for high temperatures and high pressures and still allow for many measuring points. Because we use special soldering, the unique multipoint temperature sensors are especially suitable for high temperatures and high process pressure.

The result is this specific sensor designed especially for the customer as a multipoint sensor with 20 measuring points of ø8 in 1 flange, suitable for a passage diameter of ø 65 mm. It is very important for the customer in this situation that drilling 20 holes in his hydrocracking / hydrotreating reactors is not needed, which decreases risk by 20 times. In the case of this design, the customer only has one opening through which 20 measuring points enter the reactor. This greatly reduces the risk.

A tailor-made solution for every temperature challenge

In addition to this solution, other options are also possible, but the advantage of this solution is that we can keep the surface area of the process connection as limited as possible and this was a key requirement for this application. Every temperature challenge requires a solution that best meets the needs of that moment. That is exactly what Thermo-Electra is specialized in. By translating wishes into concrete temperature solutions, we develop and produce unique temperature sensors that meet the most diverse requirements. Curious what we can do for you? Please contact us.